Joints are truly very efficient and are reliable methods of ensuring profiles are connected to one another. These days, though, having an installed aluminum profile or steel profile or stainless steel profile or skirting provides that extra finished and professional look to the home. Most of the time, people try to join profiles by cutting them at a 45- degree angle; this creates quite a ragged edge. A neat and seamless connection can be achieved, though, through using the joints

Why Use Joints for Connecting Profiles and Skirtings?

Joints serve multiple purposes when installing aluminum profiles, stainless steel profiles, and Aluminium skirtings:

- Better Alignment: Ensure that the profiles fit together perfectly without gaps.

- Stronger Connections: They enhance the durability of the installation.

- Neat Appearance: Give a polished and seamless finish, eliminating the need for rough 45-degree cuts.

- Easier Installation: Cutting each piece at 45 degrees is difficult, while using joints simplifies the process.

Where Are Joints Used?

- Middle Profile Joins

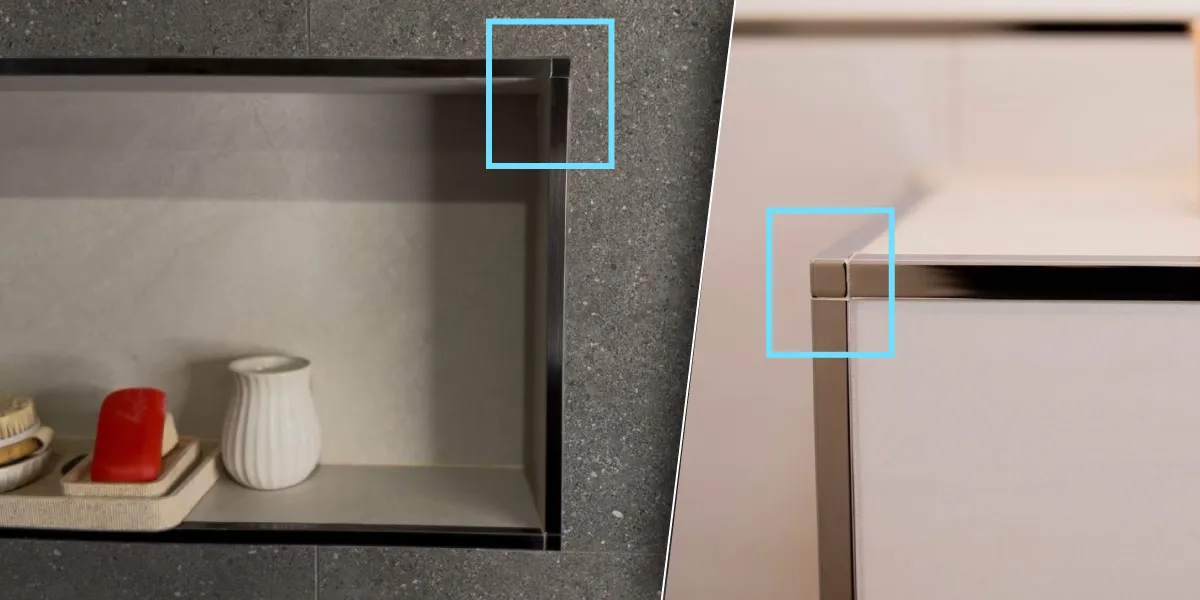

When two profiles meet in the middle, joints are required to create a seamless transition and ensure a clean finish at the edges. This applies to both aluminum and stainless steel profiles. - Outer and Inner Corner Joins.

The joining of profiles from the inside corners will smoothen the finish of the work.

Without the joints, it may be even entirely uneven and out-of-level. - Boxed Structures Narrated Above: Bathroom, Cabinets, and Partitions.

In comparison, at a place such as a bathroom, where profiles made a box-like space, joining would become difficult if no joint is kept.

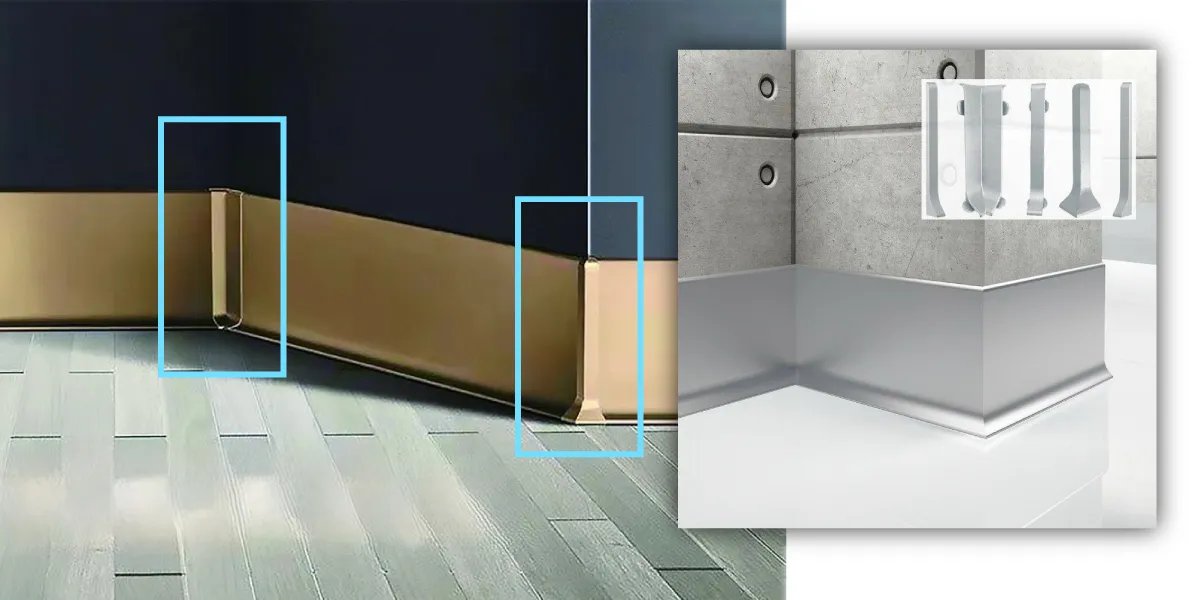

The joints would enhance the beautification needed and provide a very strong and clean connection. - Skirting-to-Skirting joints

Joints are applied for making connections between skirting to skirting so that a clean and seamless finish is obtained. Therefore, they are used to conceal the connection between profiles and to have a smooth edge which translates into beauty.

Step-by-Step Guide to Connecting Profiles

- Position the profiles first. Arrange the profiles in the right position according to the installation plan.

Check alignment before inserting . - Insert the joints at the end.

Insert joints into the profile slots, with the correct alignment, for exact alignment and tight fit. - Press the profiles firmly into the joints.

Insert the profiles into the joints until they lock securely in place. With properly sized joints, no adjustments are needed, ensuring a seamless and stable connection. - Test Stability.

Test if after connecting the profiles, the joints are all holding them.

Loose areas should be pressed together.

If needed, re adjust the joint to have a tighter fit. - Final Adjustments for a Seamless Look.

Check if the profiles are aligned. Make small adjustments, if necessary, to have a proper smooth finish.

All joints should perfectly match up to the profiles, giving a clean, professional accent.

Perfecting Profile Connections with Joints

Without joints, connecting profiles with ceramic can leave visible cuts and an unfinished look. Cutting profiles at 45 degrees is usually more challenging and may not give a smooth and flawless finish. By using joints, profiles connect smoothly without the need for cutting, resulting in a clean and polished appearance This is the best way in refurbishing and improving the aesthetics while protecting the respective profiles whether they be aluminum profiles, stainless steel profiles, or aluminum skirting as to give them a very professional and refined finish when installed.

Common Mistakes to Avoid while using Joints

- Using Wrong Joint Size

Dissimilar sizes of joints may adversely affect the connection. A smaller joint will not secure the joint properly and a larger one will not fit well. Always select the correct joint, and a perfect fit will ensure.

- Not Positioning Correctly

The profiles must be properly in place before inserting the joints. Misalignment of profiles will affect the final look and stability. Hence check accurately the placement of all the profiles.

- Skipping Inspection after Installation

Always check that the joints are properly secured after installation ends. A good inspection guarantees continuity in the joint for a smooth finish.

The Advantages of Using Joints

- Quality Interior Finishing-including Modern

Interior finishing is replete with joints contributing to perfect finishing, making it possible in both residential and commercial buildings. - Use for Durability under High Temperature

Aluminium and stainless steel profiles are used in constructions for their properties of resistance to heat.

Up there, make them last longer without warping or misalignments. - Quick and Efficient Installations

Using joints would speed up the process since it would cut the angle at 45 degrees. It would greatly benefit contractors and builders who are looking for widely available solutions in the most part of the UAE, which does factor into construction projects by precision and efficiency.

Conclusion: Why Joints Are the Best Choice for Connecting Profiles and Skirtings

To achieve a neat, professional, and durable finish when it comes to profiles and skirtings, there is no better solution than using joints. Save the hassle of cutting into precise angles and achieve a seamlessly perfect connection using it properly. Whether working with aluminum, stainless steel and Aluminium skirting ensures all of your solutions are secure and aesthetically pleasing.

This step-by-step guide will provide you with installation methods to guarantee that your profile and skirting installations are mechanically sound, visually seamless, and pleasing in their appearance.

For high quality joints comprising aluminum profiles, stainless steel profiles, and skirting solutions in the UAE make sure you choose the finest materials integrated with good installation techniques.

Frequently Asked Questions (FAQs)

Why use joints instead of cutting profiles at a 45-degree angle?

Using joints instead of cutting profiles at a 45-degree angle means that the resultant surfaces will have a no-string joint. A 45-degree angle cut can be troublesome and not really nice. Meanwhile, a joint gives any profile much better looks, as well as durability.

How do joints improve the finish of profiles?

A joint takes away the sensation of a mere cut edge by giving it a transition that finally spells a smooth flow from one profile edge to the other profile edge while ensuring that the joined profile holds its mechanical integrity.

What types of profiles are compatible with joints?

Many profiles can accept joints; they are suitable for aluminum profiles, stainless steel profiles, and aluminum skirting, among other similar profiles.

Do joints require modifications to the profiles?

Joints differ in the fact that they do not necessitate any modifications to the profiles. They are fixed without cutting or changing their original shape.

Are joints durable for long-term use?

Joints are durable for permanent use. They firmly hold the safety mechanism in place for the long run without much care and attention.