Automatic tile cutting machine is a high-performance tool designed for tilers, carpenters, and small workshops who require precise, effortless cutting. Stone, aluminum, wood and copper – this instrument, with its performance of 4500 Watts, automatic tile cutting machine ensures smooth cuts through a variety of products with accurate cuts with minimal effort.

It is really a machine that is amply equipped: an adjustable speed, laser positioning, an automatic return function and remote control operations make cutting straight, bevel cutting, round edging and grooving very easy indeed.

In this blog we will discuss the key features of the shijing Automatic Tile Cutting Machine , a step-by-step assembly guide, and techniques for cutting different ways.

Key Highlights of the Automatic Tile Cutting Machine.

- Versatile Cutting Capabilities

Cuts thin materials of not less than 3mm and as thick as 5mm.

Works on porcelain slabs, stone, aluminum, wood, and copper.

Guaranteed smooth chip-free cuts for that professional finish. - High Precision with Laser Positioning

Precise cuts are delivered by the inbuilt laser positioning.

Perfect edges and trims can be achieved. - Multi Cutting Functionality

Vertical cutting or tile chamfering; special shape cutting.

Straight cuts, bevel cuts, round edge cuts as well as grooving. - Advanced Automation and Convenience

Automatic return function improves workflow productivity.

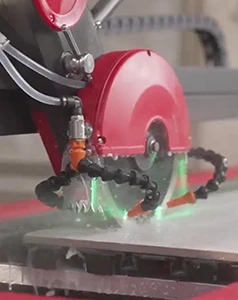

Cool the blade and reduce the dust with adjustable water spray nozzles.

Hands-free operation via built-in voice control.

A must have tile chamfering machine for workshops - Easy to Maintain and Transport

Drawer-style water tank to clean and maintain it easily.

Dual lifting wheels for easy transportation.

How to Assemble the Automatic Tile Cutting Machine

Step 1: Unbox & Check All Accessories

Open the side feet of the Automatic tile cutting machine.

Ensure all parts and accessories are included.

Step 2: Install the Water Collection Tray

Remove the water trap, ensuring sealing rings remain in place.

Place the trap under the water collection tray.

Step 3: Fit the Caster Assembly

Align the caster frame with the machine.

Screw in the hitch using screws from the tool bag.

Step 4: Install the Handle

The tool bag includes two screws unscrewed from handles.

Align and attach to the machine.

Securely tighten the screws.

Step 5: Assemble the Extension Bracket

Connect the extension bracket to the support rod and screws.

Two screws with nuts from the tool bag attach the bracket.

There are quick-lock screws fastening the crossbar into the extension bracket.

Leverage underneath the support frame by adjusting leveling screws to position.

Step 6: Connect the Water Tank

Connect the water pump using the hose to the machine.

Get the powered up water pump restored to the power supply for water to effectively flow through.

Adaptable water spray nozzles can be tested for effective cooling purposes.

Techniques of Cutting with the Automatic Tile Cutting Machine

- Straight Cut & Special Shape Cutting

Usually, these plates have their inner holes with a dimension of 24.44mm.The inner hole conversion pad should be fitted first. Then the cutting disc is aligned and installed with its press plate.The screws should be tightened. Lastly, the protective cover should be fitted.The machine should be set according to the instructions in the manual, and the cutting depth device should be locked.When making special shape cuts, utilize a T-shaped blocking stick or an angle-adjustable blocking stick.Adjust to the required angle; then fasten the screws. - Bevel Cutting

Loosen the lock on both sides of the collar.Fit in the cross beam and adjust it to the required angle.Lock the cross beam.Set the depth of cut according to the manual.You are now set for cutting at a bevel angle. - Round Edge CuttingAlign and install the rounding wheel.Press it with the press plate and screw it tight.Fix the protective cover.Adjust the machine according to the manual and lock the cutting depth device.Ensure sufficient water flow for giving a smooth finish.And now, you are set to round your edges.

- Grooving

Align and install the grooving wheel.Press it with the press plate and screw it tight.Fix the protective cover.Adjust the machine according to the manual and lock the cutting depth device.And you are set to groove on tiles.

Maintenance and Safety Measures.

- Keeping the water tank and nozzles clean will prevent blockages.

- Use of safety goggles and gloves while operating the machine is recommended.

- Ensure the proper blade settings before any cutting.

- Work in absence of moisture and with no unnecessary things inside the outlined area.

Why Choose the Shijing Automatic Tile Cutting machine?

For the power, precision power, and many cutting functions which suit varied application needs, the shijing Automatic Tile Cutting Machine should be your best bet for a cutting machine for tile. From tile chamfering in UAE to a versatile trim machine across the board, this piece guarantees efficiency and precision in whatever cutting activity you may be looking to perform.

Make the upgrade today and give your workshop a thrilling, professional cut.

Conclusion

Shijing Automatic tile cutting machine that offers power and versatility ideal for tilers, carpenters, and small workshops. With high precision, multiple cutting functions, adjustable speed levels, and laser positioning, this machine enables the cutting of various materials, including stone, aluminum, wood, and copper, like a pro.

Automatic return, adjustable water spray nozzles, drawer-type water tank make this machine quite efficient, simple to care for and user-friendly. Straight cuts, bevel cuts, chamfering, or grooving, this machine is designed for precise and hassle-free results.

The automatic tile Cutting machine is the best option for those looking for a cutting machine for tile, a tile chamfering machine, or tile trim in UAE. Upgrade your workshop and get precision cutting beyond your imagination today.

Frequently Asked Questions (FAQs)

Which materials can be cut with the shijing Automatic Tile Cutting Machine?

The shijing Automatic tile cutting machine can cut stone, aluminum, wood, copper, and porcelain slabs having a thickness from 3- to 5-mm.

Can this machine be utilized for various cutting techniques ?

Yes, it is suitable for straight-cutting, bevel cutting, round-edge cutting, grooving, vertical cutting, and tile chamfering.

What is the advantage of the water spray system in Automatic tile cutting machines ?

The adjustable water spray nozzles cool the blade, reduce dust, and give a longer blade life for effective cutting.

Is the machine easy to carry around?

Yes, the dual lifting wheels allow moving the machine easily, even in small workshop areas.

Does the shijing tile cutting machine have an automatic return function?

Yes, the functionality contributes to efficiency by resetting the cutting position after each cutting.

How do I assemble the automatic tile machine?

The assembly is basically done by installing the water collection tray, attaching the caster frame, installing the handle, setting up the extension bracket, and connecting the water pump. Maintenance and setup of the machine are made easy.